PRODUCT

صفحة رئيسية>منتجات>

feeding size of iron ore in primary crusher

Primary Crusher Optimisation for Improved Comminution

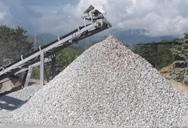

The primary crushers take blasted, run-of-mine, or run-of-quarry feed up to 1500 mm and produce a product ranging in size from -300 mm for conveyor transport, or -200 mm for SAG mill feed.2016年1月1日 The feed size to a primary crusher from the mines could be 1–1.5 m; thus, the maximum product size possible is 10–15 cm which is normally too large for down Gyratory and Cone Crusher - ScienceDirectFigure 6.4 is a typical set-up where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size Primary Crusher - an overview ScienceDirect Topics

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation Primary Crushing. The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary AMIT 135: Lesson 5 Crushing – Mining Mill Operator A Jaw Crusher is one of the main types of primary crushers in iron ore processing plant. The rectangular or square opening at the top of the jaws (feed opening) designates the COMMINUTION - THEORY AND PLANT PRACTICE

Primary Crushing SpringerLink

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below While blasting produces the ultra-fine material beneficial to mill throughput, the crushers are used to control topsize and critical size material generated in the blast. Image analysis The Importance of Primary Crushing in Mill Feed Size Optimization

- طين البنتونيت في مطحنة في فيكتورفيل كاليفورنيا في ميريك لنا

- فهرست مواد معادن

- prosedure الفحم المتنقلة سحق

- تقرير مشروع معجون الجدار الداخلي

- فيلم تكسير كسارة صغيرة

- صخرة الخبث مقابل صخرة الغبار محطم

- تكوين محطة تكسير الحجر 100tph

- الكرة محطم المصنعين الهند

- تشنغتشو Xinguang تصنيع آلات التعدين المحدودة

- كيف محطم الخرسانة المحمولة تعمل

- صنع مروحة هوائية

- المحمول محطم خام الحديد للبيع في أنغولا

- جديد هولندا 352 تغذية مطحنة

- تراب قمائن صور لحام إصلاح الكسر

- مصنع سحق باكستان وآلة

- ماذا عن المنتجات المنتجة في المعادن من خلال التعدين

- كيفية طحن المعادن إلى مسحوق

- تدفق معالجة خام النحاس

- خام الذهب تصنيع آلة المحمولة

- حذف بتن سنگ شکن در مسکو