PRODUCT

صفحة رئيسية>منتجات>

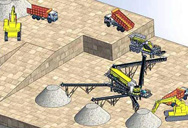

continuous mining rod millcontinuous mixer iron ore pellet plant australia

CO2‑Free Flux for Sustainable Iron Ore Pelletizing

In the present work, the authors established a novel CO2-free flux called wollastonite (CaO.SiO2) for sustainable palletization. Pellets with varying percentages of wollastonite 2024年3月4日 It is possible to use wollastonite fluxed iron ore pellets as a raw material to minimize the flux input in blast furnaces. Therefore, the development of wollastonite CO2-Free Flux for Sustainable Iron Ore Pelletizing Mining, Benefits. Optimal plant performance and lowest TCO (Total Cost of Ownership) Produces pellets with excellent metallurgical and physical properties for both the blast furnace and NextGen Pelletizing™

Iron ore pelletizing - Metso

Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest 1. Iron ore - supply and demand outline. 1.1 Types of iron ore. Iron ores can be classified in different ways. The most important has to do with the iron content. In many cases, ore Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade ...2018年7月11日 The iron ore pellet holds a pivotal role in the ironmaking process, enabling the utilization of high-grade ore and the upgrading of low-grade deposits [1]. (PDF) Iron Ore Pelletizing Process: An Overview - ResearchGate

Digital Solutions for Iron Ore Pelletizing Plants

Improve process performance, production capacity, and product quality of iron ore pelletizing processes. Reduce energy consumption, environmental impact, and operation The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives —anthracite, dolomite—and Iron Ore Pelletizing Process: An Overview - IntechOpenPelletization at ArcelorMittal Mining Canada’s pellet plant involves enriching iron ore and converting it into pellets that are cooked at a high temperature for use in steel production. Production - ArcelorMittal Produits longs Canada

ArcelorMittal announces CAD$205 million decarbonisation

A DRI plant uses natural gas to reduce iron ore, resulting in a significant reduction in CO 2 emissions compared with coal-based blast furnace ironmaking. In Hamburg, Germany,

- ذروة كسارة الحجر اليدوي

- موبيل سحق النبات في الإمارات العربية المتحدة للتأجير

- قضيب صناعي للبيع في مصر

- در gandhinagar سنگ شکن

- اصنع آلة الطحن الخاصة بك

- سحقمن عملية الزجاج المكسور

- اقتباس من كسارة مخروط الهند

- المهنية آلات التعدين الصانع

- جعل سحق الفك بسيطة

- سعر خط إنتاج الأسمنت بالكامل

- شركة تصنيع كسارة مخروطية في العراق

- كسارة المطرقة لتكسير الحجر

- sale of iron ore crushers machines in use

- المعدات اللازمة لتجهيز

- البناء الجبس كتلة سعر المصنع

- عمليات زرقة الذهب في ليبيا

- تشيفي الاسطوانة طحن لاعبا اساسيا

- آلة الجليد الصغيرة الحجم

- آلة صخرة الرمل في الهند

- الحفارة الرمال للبيع في الولايات المتحدة الأمريكية